New Technologies and Advanced Material

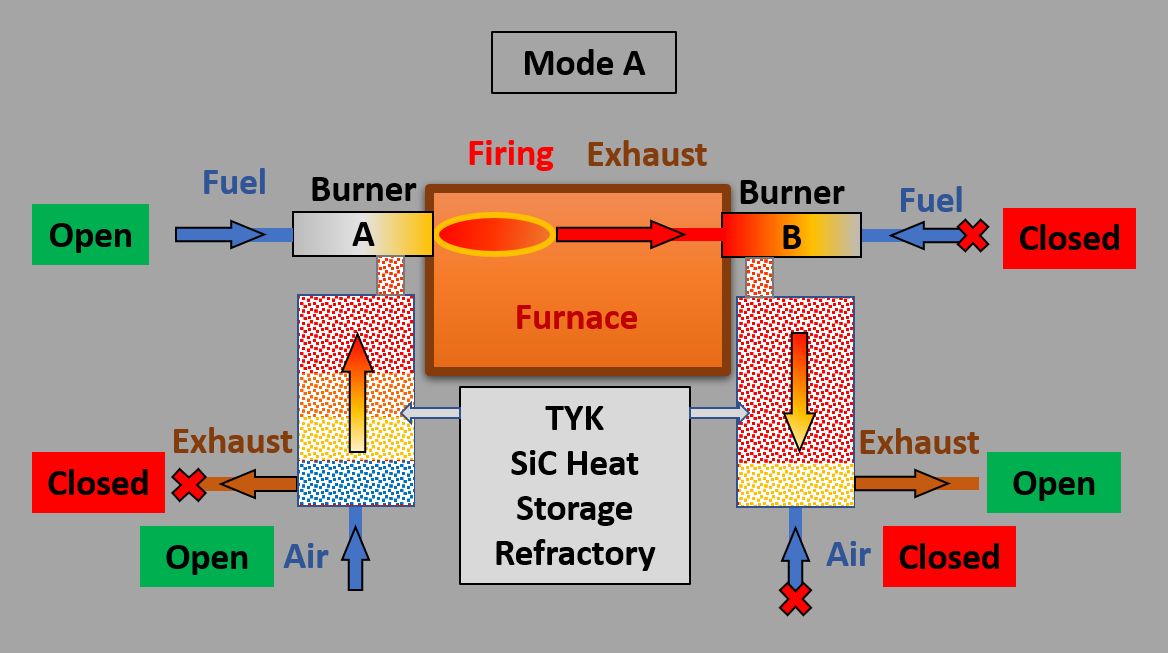

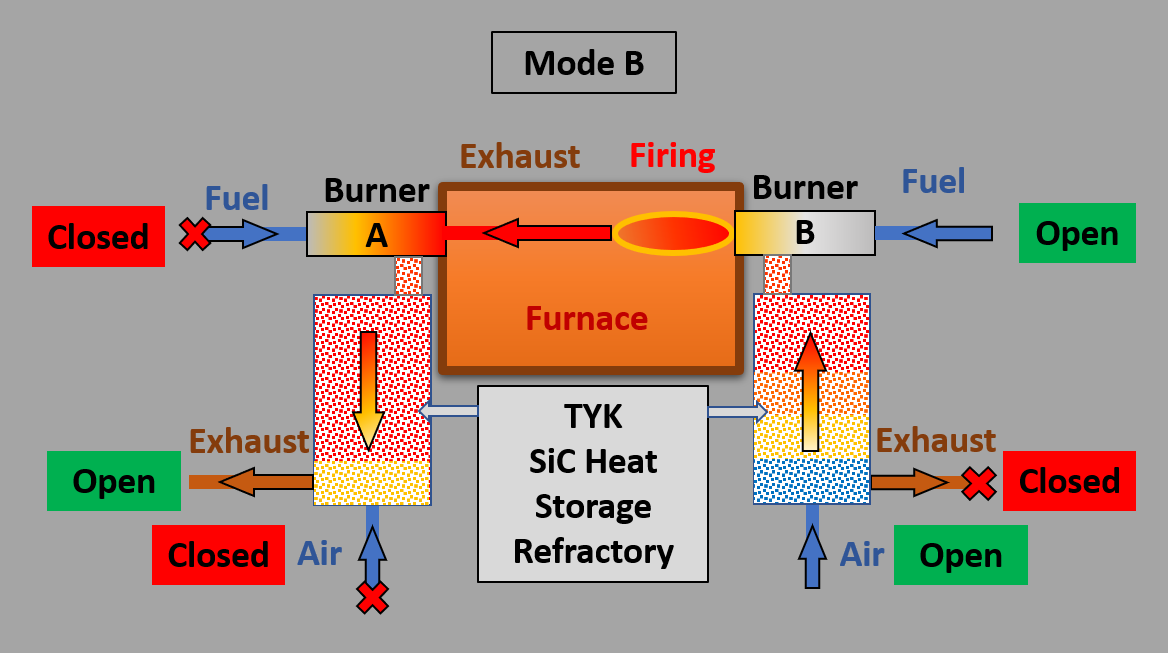

Regeneraive Burner Systems

The regenerative burner system is a combustion heating system that can recover the exhaust heat very efficiently in industrial furnaces. Since the regenerative burner system can save the cost, energy and CO2 emission by its high fuel efficiency, this system became more and more popular and is applied for rolling heat furnace, forging furnace, heat treatment furnace, melting furnace, etc.

1. Regenerative burner consists of two burners as one pair. One burner stores heat from another burner (Mode A)

2. After specific intervals (normally 15 to 60 seconds), the burner switches (Mode B)

3. By preheating combustion air through heat storage ceramics, the consumption of energy can be reduced.

Mode A

Mode B

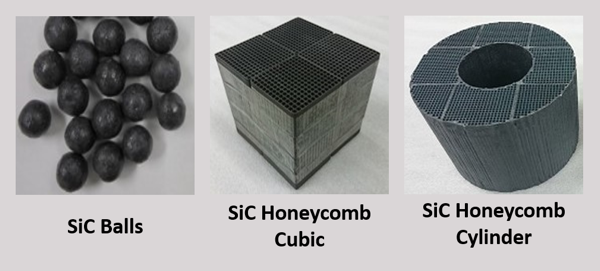

SiC Balls and Honeycomb Shapes

We supply 3 types of heat storage materials:

1. SiC Ball

2. SiC Honeycomb cubic shape

3. SiC Honeycomb cylinder shape

Samples

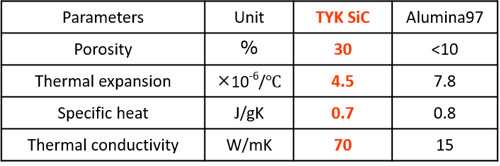

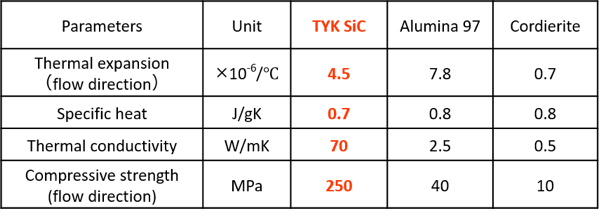

The advantage of SiC material compared with standard materials

Our SiC heat storage material has several advantages compared with the mainstream Alumina or Cordierite materials widely in use.

SiC Balls

High thermal conductivity

High thermal shock resistance

At least 2 times longer lifetime - Less Maintenance

Additional energy savings

Specification of SiC Balls

SiC Honeycomb

High thermal conductivity

High thermal shock resistance

At least 10 times longer lifetime - Less Maintenance

Additional fuel efficiency

Specification of SiC Honeycomb

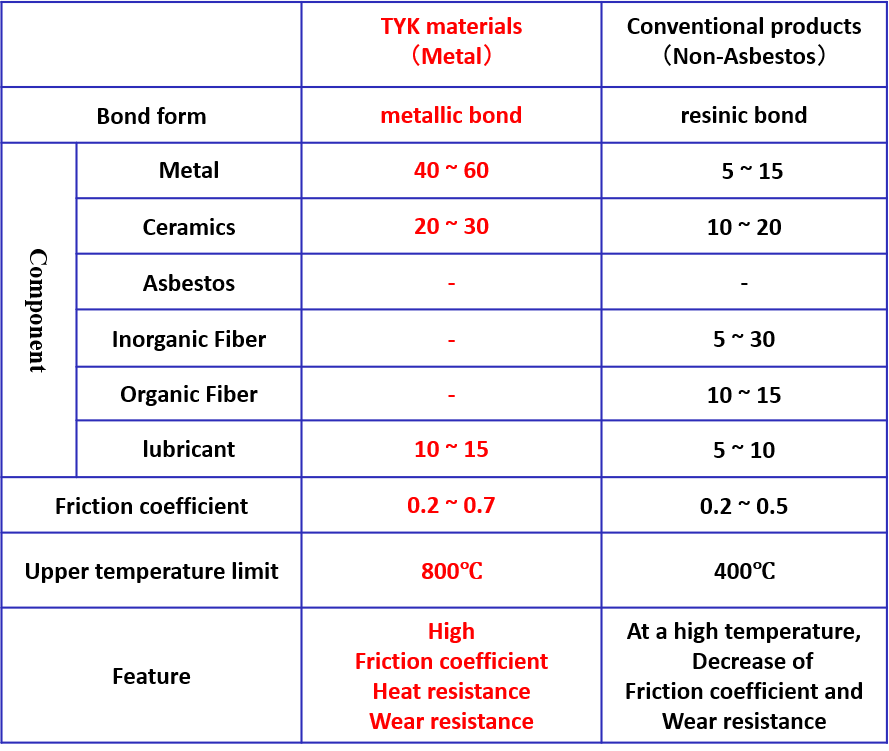

Brake Pads

Metallic Friction Material for Brake Pads

Applications

Specification

The Advantage of Metallic Friction Material compared to Resin Bonded Material

High friction coefficient

No outbreak of the fade phenomenon

Superior wear resistance

Environment friendly material

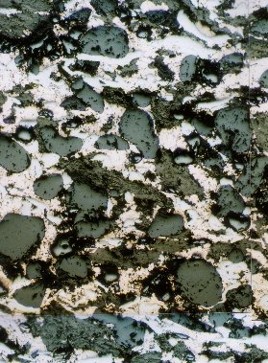

Structure

Zirconia Ceramic Screen "Grizzly Bar"

The Advantage of a Ceramic Screen

Application